Plastics are synthetically made non-metallic materials. It could be molded into different forms and hardened for industrial use. Plastic Injection Molding products could be seen everywhere. Examples are bottles, protective caps, plastic pipes, grips, toys, jars, cases, accessories, kitchen tools and a lot more.

Even the computer keyboard and the computer mouse that you use are produced through Plastic Injection Molding. Even the plastic components of the chair that you are sitting on are created in this way.

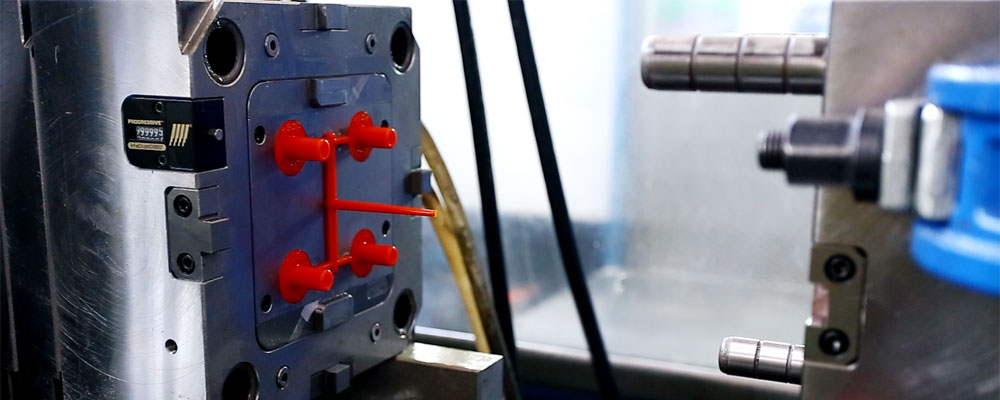

The basic idea in Plastic Injection Molding is placing molten liquid plastic into a readily shaped mold, such as the mold of a bottle. It will be then allowed to cool, then the mold will be removed to reveal the plastic bottle.

Plastic Injection Molding can also custom-mold a wide range of plastic products including: garden pans, cupboards, office trays and containers, barriers, barricades and traffic signage and displays for product and marketing promotions.

If you are planning to engage in Plastic Injection Molding business, you should first know the different processes. Select from a Plastic Injection Molding process that suits your budget plan, your expertise, and your resources. Here are basic interpretations of different methods of Plastic Injection Molding.

The Plastic Injection Molding Processes:

Injection Molding

In Injection Molding, melted plastic is injected a mold cavity. Once cooled, the mold can be taken out. This Plastic Injection Molding process is often used in mass-production or prototyping of a product. Injection molding machines were made in the 1930’s. These could be used to mass produce toys, kitchen tools, bottle caps, and mobile phone stands to name a few.

Blow Molding

Blow molding seems like injection molding except that hot liquid plastic pours out of a vessel vertically in a molten pipe. The mold closes on it and compels it outside to comply with the inside shape of the mold. When it is cooled, the vacant part is formed. Examples of blow molding products are bottles, pipes and containers.

Equipments needed in setting-up a blow molding business are really higher than injection molding.

Compression Molding

In this kind of Plastic Injection Molding, a slug of hard plastic is pressed between two heated mold halves. Compression molding usually uses upright presses rather than the horizontally presses used for injection and blow molding. The parts formed are then air-cooled. Prices of equipments used for compression molding are medium.

Film Insert Molding

This Plastic Injection Molding technique inserts an image beneath the surface of a molded part. A material like film or fabric is inserted into a mold. Plastic is then injected.

Gas Assist Molding

Called gas injection molding is used to create plastic parts with hollow inner parts. Partial shot of plastic is then followed by high-pressure gas to fill up the mold cavity with plastic.

Rotational Molding

Hollow molds loaded with powdered plastic are secured to pipe-like spokes that stretch from a center hub. The molds spin on separate axes at once. The core swingings the whole mold to a closed furnace room causing the powder to melt and stick to the insides of the moulds. As the molds turn slowly, the tools move into a cool room. Here, splashed water makes the plastic to harden into a hollow part. In this kind of Plastic Injection Molding, mould costs are low and piece prices are high. Cycle time takes about 40-45 minutes.

Structural Foam Molding

Structural foam molding is a process of Plastic Injection Molding normally used for parts that need thicker walls than standard injection molding. Inserting a small volume of nitrogen or chemical blow agent into the plastic material makes the walls thicker. Foaming happens as the melted plastic material enters the mold cavity. A thin plastic skin forms and strengthens in the mold wall. This type of Plastic Injection Molding could be used with any thermoplastic that can be injection molded.

Thermoforming

Within this Plastic Injection Molding process, pieces of pre-extruded rigid plastics are horizontally heated and pulled down into hollow one-piece tools. When the hot plastic strengthens, its shape conforms to that of the mold.

Mould costs are commonly low and piece prices can vary on the machinery.

Plastic Injection Molding is a very specialized process. It needs professionals in this type of manufacturing business for it to become competitive in the market. A very technical and scientific study should be primarily made before going into this endeavor.

Get A Free Quote