Looking for a Plastic Injection Molding and Die Casting company that can turn your design into a real product?

You’ve found it. Whether your design is professionally developed or simply drawn on a napkin, Imould Tech can turn your idea into reality.

When comes to Plastic Injection and Die Casting, Imould is second to none.

Imould Tech skilled and experienced teams are ready to help you take your project all the way from initial design through development, tooling and assembly.

Start with a free project review

What we can do

We have the software, processes, tools, and most importantly, the experienced people necessary to accomplish your job. You can rely on us to take your business seriously and protect your interests. We allow you to focus on your business, while we take care of the tooling, the injection molding and die casting process, the assembly, and the delivery of quality finished products.

What services does Imould Tech offer

Engineering and Prototype

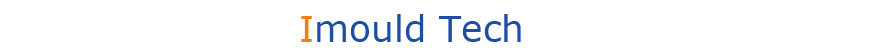

A good design is the heart of a mold, and Imould Tech pays special attention to the mold construction, cooling channels and moving mechanisms to ensure the highest quality parts are delivered from your mould at the minimum cycle. All moulds are carefully designed to maximize service life and ease of maintenance.

We can provide CNC, SLA or SLS prototypes for our clients.

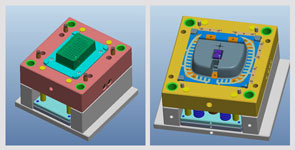

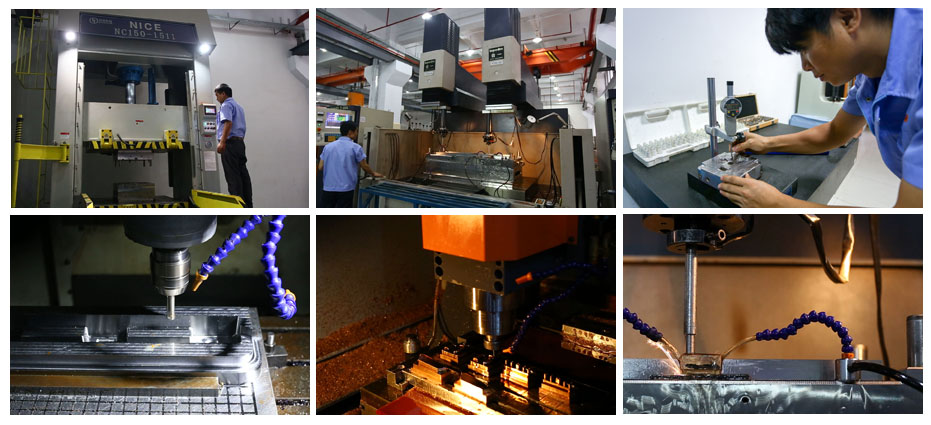

Mould Making

Plastic Injection Mould and Die Cast Tooling making is our main business. Imould Tech is well-known in the industry for its capability to manufacture highly complex and highly productive moulds with unsurpassed workmanship. Imould Tech makes moulds from single to 100 cavities incorporating multiple slides and lifters, collapsible or expandable cores, multiple hydraulic core pulls or unscrewing mechanisms, hundreds of interchangeable inserts, numerous and shutoffs with demanding requirements for appearance and dimensional accuracy. Our engineers collaborate closely with our customers on all aspects of the programs so as to develop the best designed moulds that are easy to maintain and plastic components that are cost-effective to produce.

How to work

2, Product design

3, Make the prototypes

4, Product Testing

5, Mold design

6, Mold making

7, Try out the moulds

Injection Moulding

A full range of moulding machine enables Imould Tech to offer very small precision parts as well as large aesthetic housing parts.

Robotic arms are also employed to automate the process and improve process stability and moulding quality.

Imould Tech expertise in moulding can offer plastics solutions that other competitors cannot offer, including specialized process like 2 shot injection, IMD, IML, Gas assisted injection moulding, insert moulding, over-moulding, thin wall injection moulding and 100,000 class cleanliness moulding.

Surface Finishing and Secondary Operations: Painting, Silkscreen, Pad Printing, Heat Transferring, Hot Stamping, Laser Marking and Ultrasonic Welding are just some of our capabilities.