If you are looking for a China plastic mold and die casting company that is ISO 9001:2008 certified, with a wealth of technical experience within our industry, as well as a vast array of equipment, then you have found us – Imould!

What we can do

We created our Plastic Mold and die casting tooling promise: for your peace of mind. You should feel secure leaving your Plastic Mold and die casting tooling with us.

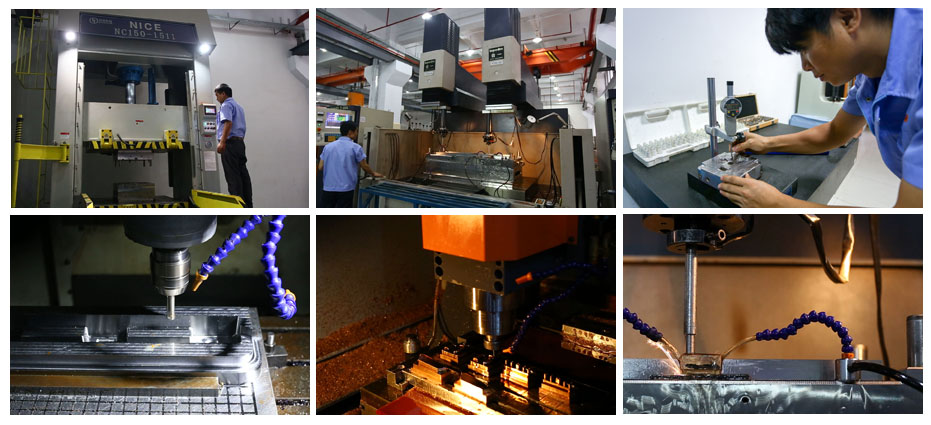

Mould Making

Plastic Mold and Die Casting Tooling making is our main business. Imould Tech is well-known in the industry for its capability to manufacture highly complex and highly productive moulds with unsurpassed workmanship. Imould Tech makes molds from single to 100 cavities incorporating multiple slides and lifters, collapsible or expandable cores, multiple hydraulic core pulls or unscrewing mechanisms, hundreds of interchangeable inserts, numerous and shutoffs with demanding requirements for appearance and dimensional accuracy. Our engineers collaborate closely with our customers on all aspects of the programs so as to develop the best-designed moulds that are easy to maintain and components that are cost-effective to produce.