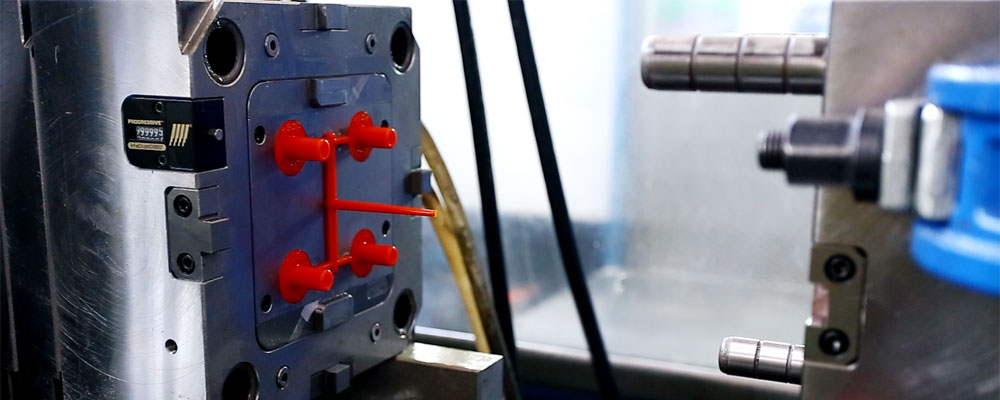

Imould Tech has an impressive range of plastic injection molding capacity, varying from 30 tonnes up to 700 tonnes. This selection includes the ancillary Plastic Injection Molding equipment such as: heaters, dryers, hot runner controllers, conveyors and much more.

Plastic Injection Mould Tooling

we can provide your injection moulded parts in any standard injection mouldable polymers and in any volume you require. Because of the diverse range of industries we’re involved in and the requirements they bring, we have the capacity to be able to provide extremely low volume (usually for concept or approval) or low to medium volume production. In addition, we can over-mould any number of threaded inserts, metal fret connectors or other plastic injection parts to give your low-volume product a professional finish.

Full Service Plastic Injection Molding

Sub-assemblies can also be created, and packaged to your requirements. The same applies for various finishing processes, including: